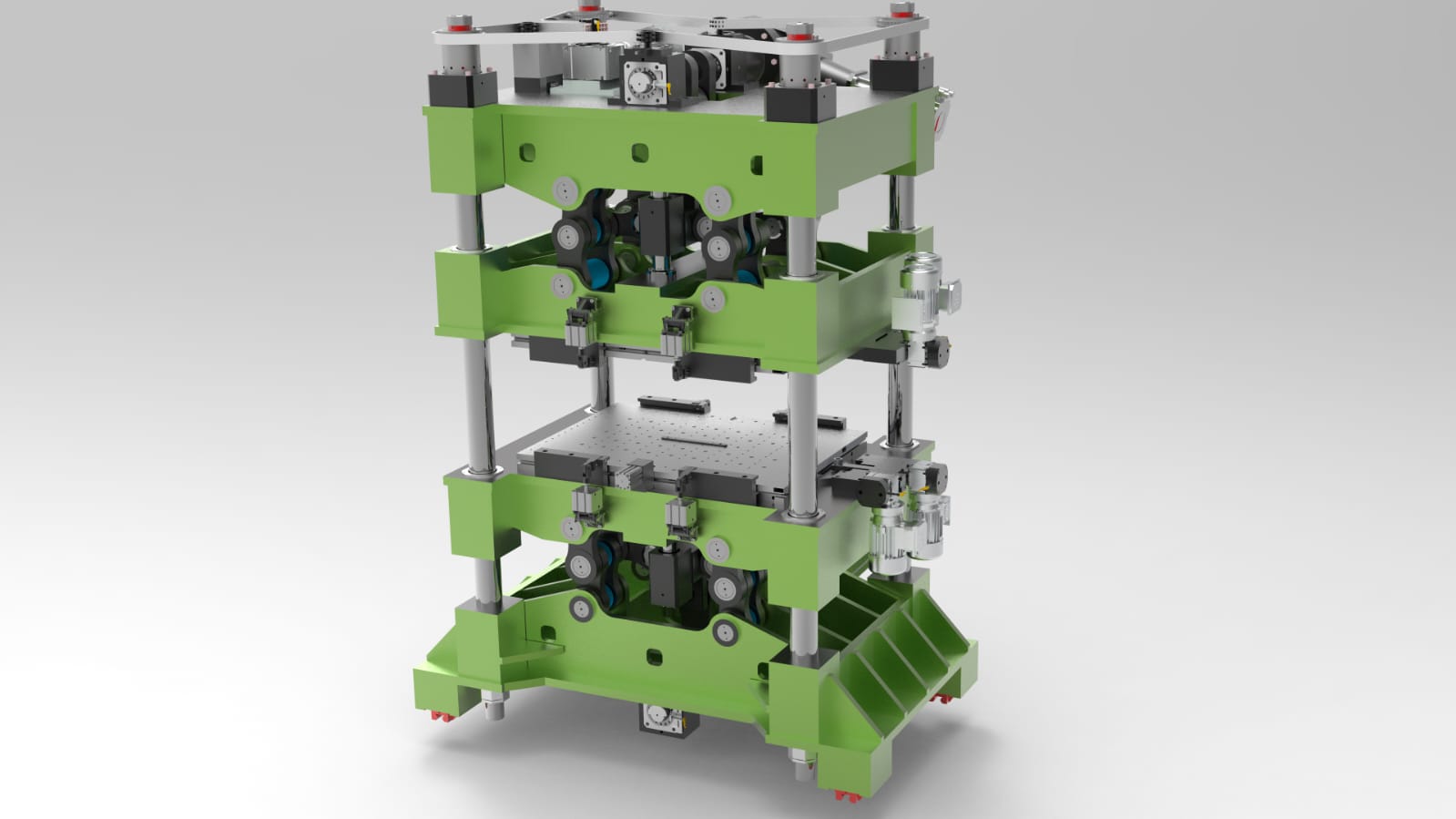

UTM Series Thermoforming Machines

Developed by UTM’s R&D team, these machines are ideal for producing disposable plates, lids, bowls, trays, and fruit or vegetable containers. They work with various plastic materials such as PP, PET, and PS, using a servo-driven, three-station system for forming, cutting, and stacking. The built-in automatic lubrication system ensures low maintenance and high productivity.

-

Stacking station

In thermoforming machines, the stacking station ensures that the products that have completed the shaping and cutting processes are stacked on top of each other in a neat and orderly manner. This unit stacks the products in certain numbers and makes them ready for packaging, increasing the automation of the production process. It protects product quality and saves labor by preventing faulty stacking.

-

Cutting Station

In thermoforming machines, the cutting station is the section where shaped and cooled plastic products are cut to the desired dimensions. This station usually uses cutting blades or laser cutting systems to remove the products from the mold and separate them to the specified dimensions. The cutting station ensures that the products reach their final form and is in the final stages of the production process. In addition, cutting the products smoothly and without errors plays a critical role in quality control.

-

Robot

In thermoforming machines, robots usually play a role that automates and speeds up the production process. Robots perform operations such as removing, transporting, placing, stacking or packaging plastic products in particular. This reduces labor, minimizes errors and increases production speed. In addition, robots allow products to be processed properly and in high quality thanks to their ability to make precise and repeatable movements. Thus, a faster and more efficient production process is achieved.

-

Elevator

In thermoforming machines, an elevator is a mechanism that allows plastic products to be moved from one level to another during the production process. It is usually used to lift or lower products after forming, cooling or cutting processes. This system helps to place products neatly in the transport area or stacking station. Elevator increases the efficiency of the production process, allowing products to move quickly and safely. It also provides automatic transportation without the need for manual intervention by operators.

-

Scrap Winder

In thermoforming machines, **scrap winder (waste wrapping unit)** is a device that ensures that plastic waste generated during the production process is wrapped and collected properly. The task of this unit is to collect the plastic material that is cut or not used during thermoforming and wrap it in an orderly manner. Scrap winder provides efficient storage of waste materials, thus facilitating both cleaning of machines and collecting waste that is suitable for recycling. This system plays an important role in keeping the production area tidy and recycling waste.

-

Lubrication Units

In thermoforming machines, **lubrication units** are systems used to ensure the smooth operation of the moving parts of the machines. These units regularly inject oil or lubricant into the various components of the machines, reducing friction, preventing wear and preventing overheating. This lubrication system is especially critical for mold transport mechanisms, forming stations and other moving parts. This extends the life of the machines, increases efficiency and reduces the possibility of failure. It also minimizes the need for maintenance and prevents interruptions in the production process.