UTM Series Thermoforming Machines

Developed by UTM’s R&D team, these machines are ideal for producing disposable plates, lids, bowls, trays, and fruit or vegetable containers. They work with various plastic materials such as PP, PET, and PS, using a servo-driven, three-station system for forming, cutting, and stacking. The built-in automatic lubrication system ensures low maintenance and high productivity.

-

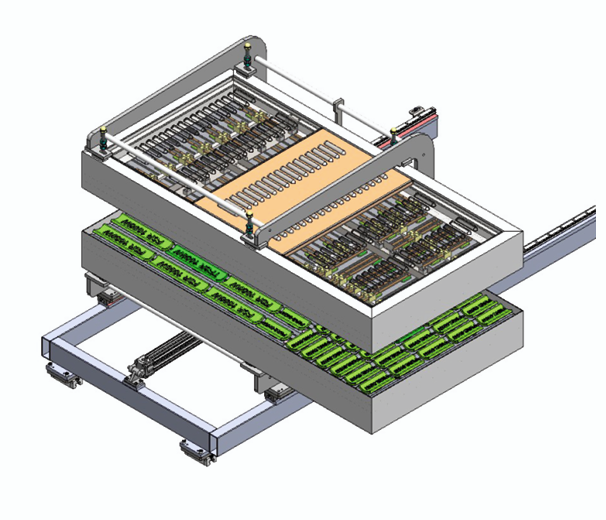

Electrical Cabinet

In thermoforming machines, the electrical cabinet is the section that houses and controls all electrical systems of the machine. It provides operations such as power distribution, temperature control, management of motor and vacuum systems. It also carries out automatic operation and safety functions with components such as PLC, fuse, relay. It is critical for the healthy, safe and efficient operation of the machine.

-

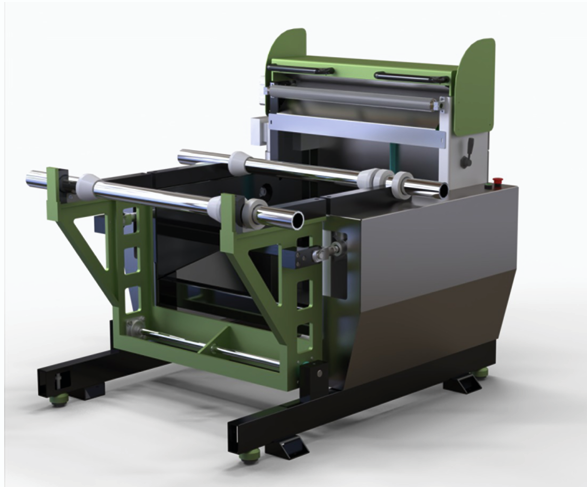

Unwinder

In thermoforming machines, the unwinder is the unit that ensures that the plastic film is unwound from the reel in a smooth and controlled manner and fed into the machine. It is located at the beginning of the production process and adjusts the film length, ensuring that the material advances without slipping, breaking and at the desired speed. In this way, proper arrangement and cutting are provided during the thermoforming process.

-

Pre-Heater System.

In thermoforming machines, preheating allows the plastic sheet or film to be brought to the desired temperature before shaping. This process helps the material become more flexible, thus allowing it to take a more regular and detailed shape in the mold. Preheating both increases product quality and reduces the risk of faulty production.

-

Heating Unit

In thermoforming machines, the heating unit (heating unit) ensures that the plastic sheet or film is heated to the appropriate temperature for the thermoforming process. This unit is usually equipped with electric resistances or infrared heaters and aims to soften the material evenly. Thanks to the heating unit, the plastic reaches the flexibility to be easily shaped in the forming mold, which directly affects the product.

-

Forming Station

In thermoforming machines, the forming station (shaping station) is the section where quality and softened plastic material is put into the mold in the desired form. In this station, the plastic material is converted into the mold by vacuum, pressure (compressed air) or mechanically and the product shape is created. The forming station is the most critical stage where the final shape of the product is determined and precise work is of great importance to obtain a quality and smooth product.

-

Punching Unit

In thermoforming machines, the punching unit (drilling/cutting unit) is the unit that finalizes the shaped plastic products by cutting around them or by opening holes in certain areas. This unit is used to separate the products coming out of the mold in the desired size and form. It usually works with a pneumatic or hydraulic system and provides fast cutting with high precision. It is the last step for the products to be ready for use.