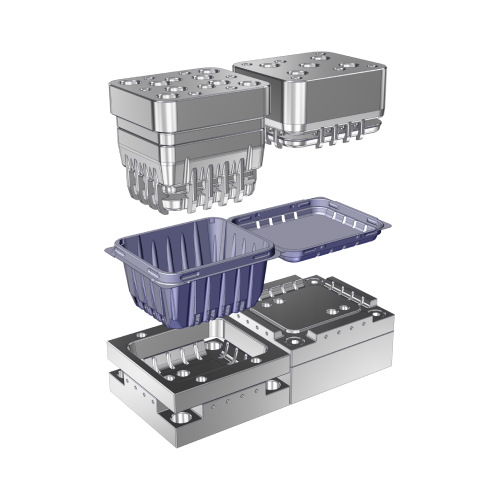

Mold Making

Professional and dedicated services.

Universal thermoforming services is your indepent advisor when it comes to selecting the right mold for each thermoforming job. We have close contacts with multiple mold makers, always enabling us to get the best deal for you.

We are excited for our work and how it positively impacts clients.

Benefits of mold making services

A correctly designed and manufactured mold ensures the same quality and dimensional accuracy in every part, which makes standardization in the final product possible.

Molds manufactured with durable and correct materials have a long service life. This reduces mold replacement, maintenance or remanufacturing costs.

Correct mold design largely prevents problems such as deformation, thin wall errors or deformations. Thus, the waste rate is reduced and waste is prevented.

Frequently asked questions

Thermoforming molds are usually made of materials such as aluminum, composite, wood or epoxy resin. The preferred material is determined by the volume of the product to be produced, the level of detail and the duration of use.

A correctly designed mold ensures that the material is shaped properly. In this way, wall thicknesses are equal, deformations are prevented and product surface quality is increased. In addition, a good design reduces the waste rate during production.

Mold making time varies depending on the complexity of the product, the materials used, and the manufacturing method. It can typically take from a few days to a few weeks .Technologies such as CNC machining or 3D printing can speed up the process.