Professional and dedicated services.

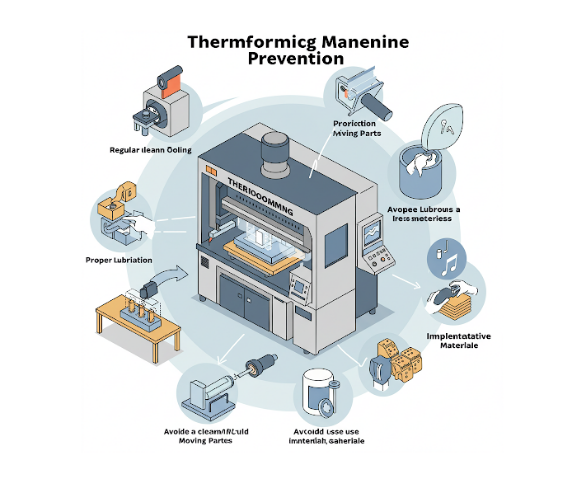

Preventative or scheduled maintenance leads to substantial cost savings long term. It’s the best way to increase your machinery’s longevity and uptime. UTS offers bespoke preventative plans made with your company’s requirements in mind

We are excited for our work and how it positively impacts clients.